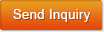

RO Purifier Plant

110000.00 - 250000.00 INR/Unit

Product Details:

- Type Water Purifier

- Material Stainless Steel

- Power 220-300 Volt (v)

- Installation Type Wall Mounted

- Water Source Submersible Pump

- Voltage 12-24 Volt (v)

- Weight (kg) 50 Kilograms (kg)

- Click to View more

X

RO Purifier Plant Price And Quantity

- 1 Unit

- 110000.00 - 250000.00 INR/Unit

RO Purifier Plant Product Specifications

- Submersible Pump

- 12-24 Volt (v)

- Wall Mounted

- 50 Kilograms (kg)

- Water Purifier

- Stainless Steel

- 220-300 Volt (v)

RO Purifier Plant Trade Information

- Cash Advance (CA) Telegraphic Transfer (T/T) Cash in Advance (CID)

- 10 Unit Per Month

- 15-20 Days

- All India

Product Description

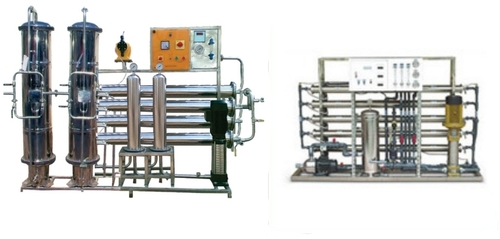

We are a well-renowned manufacturer, exporter and supplier of a wide range of the best quality Industrial RO Purifier Plant. The offered plant is used to produce high-quality dematerialized water. This plant finds usage in food processing, pharmaceutical, chemical, boiler feeding requirement, and many more. We make available different types of plant according to the tap water, brackish water & sea water application. This Industrial Reverse Osmosis System is manufactured with high level of precision using excellent quality components with the help of latest technology.

Further Details:

Reverse Osmosis (RO) is a procedure of physical partition of disintegrated minerals and solids present in water. This innovation utilizes the standard of osmosis, wherein the mineral solution of raw water is diminished by applying top force via a semi-penetrable layer.

RO innovation provides optimum adaptability to meet various demands. Our personalized programming, INDIAN facilitates clients pick up the most effective 'RO Advantage', by making the correct choice.

INDIAN regards your channel water capacity and quality needs and gives you streamlined blend. This option is reliant on various pump models, inlet water quality, flux rates and film sorts. It provides the correct solutions, diminished

Benefits of Industrial RO Purifier Plant :-

1) Small and stylish RO blocks

2) Simple installation, servicing and operation

3) Particular assortment feasible from a wide gamut

4) Superior level of plant mechanization

5) Visual checking framework for simplicity of trouble-shooting

Other Products in 'RO System' category

"Our company deals only in Commercial & Industrial Fields."